Flexible Printed Circuits

Flex circuits are flexible membrane switches made by either etching or screen-printing. Due to their thinness and ability to bend, they are often used in space-constrained applications where no other switches can fit. Flex circuits also help to solve interconnect challenges. Flex circuits eliminate the need for bulky, expensive wires and connectors, and offer a repeatable, reliable method of connecting things.

FPC provides two main types of flex circuits: Copper Flex and Silver Flex circuits.

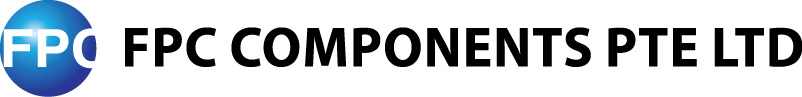

Copper Flex Circuits

Copper flex membrane switches are similar to normal membrane switches in that they are made of conductive metal traces on a thin film substrate. However, they differ in one major way: rather than directly printing the traces on, the traces are formed by chemically etching a copper-clad substrate. Chemical etching involves the use of harsh chemicals, hence copper flex circuits are much less environmentally friendly than screen-printed silver circuits. In addition, since more copper is used than needed (due to the lamination process), copper flex circuits lead to higher costs and greater wastage.

However, copper has significantly lower resistance than silver ink. Hence, copper traces can be made thinner, resulting in a much smaller, lighter, lower resistance switch. Copper flex membrane switches use either polyester (PET) or polyamide (Kapton) as the membrane substrate.

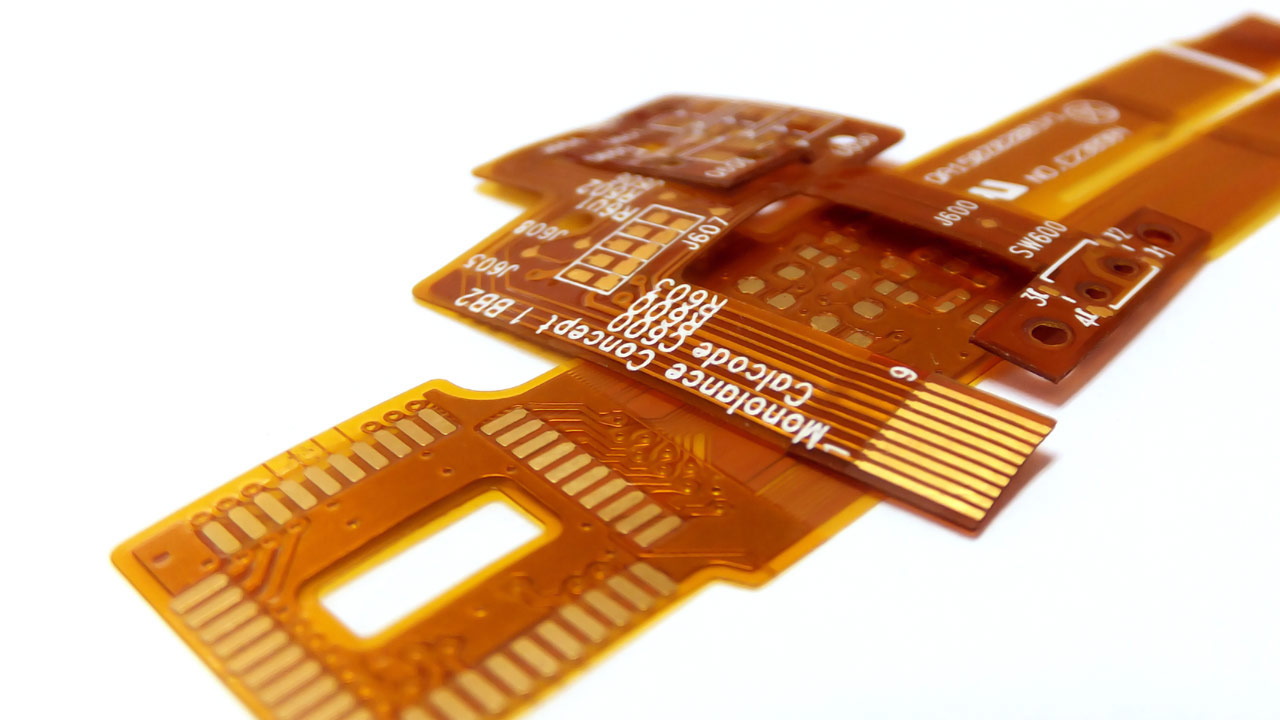

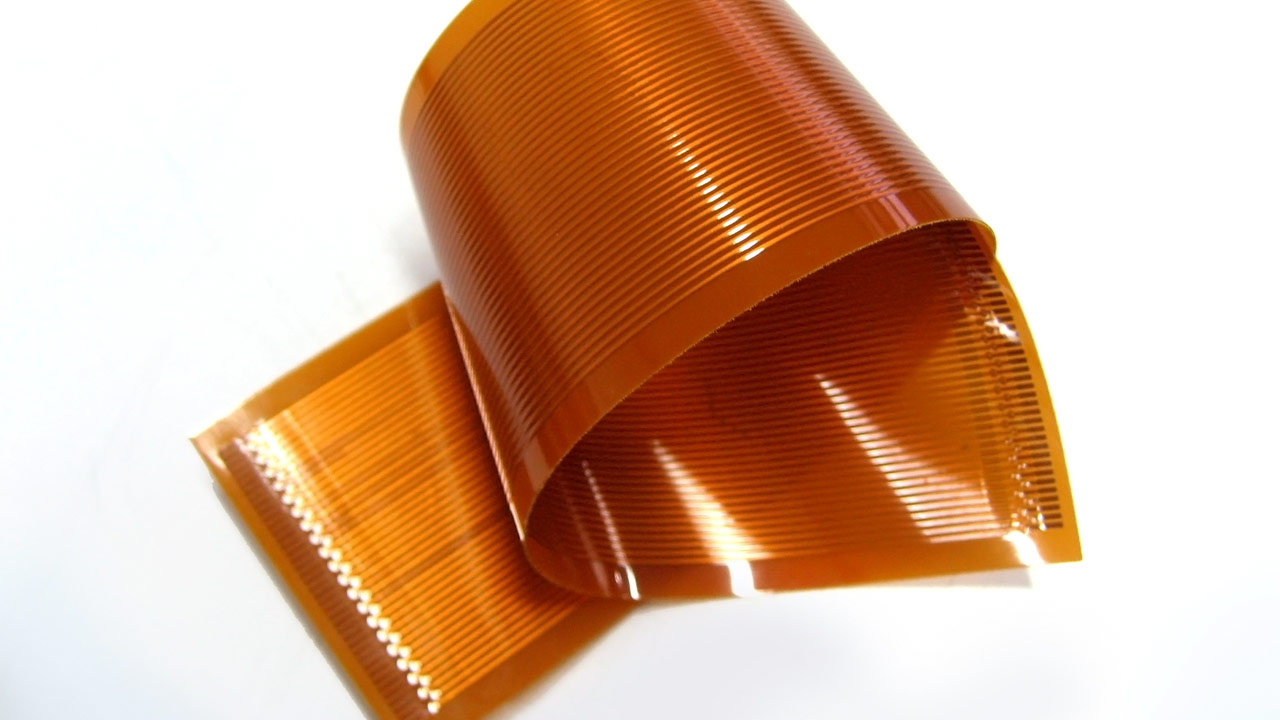

Silver Flex Circuits

Silver flex circuits are flexible membrane switches made by screen-printing silver ink onto flexible polyester film sheets. Since silver flex circuits do not use an etching process, the use of harsh chemicals is eliminated, making silver flex circuits much more environmentally-friendly and more affordable than copper flex circuits.

However, silver flex circuits have a higher resistance than their copper flex counterparts, hence the decision to choose either option should be based on the needs of each individual application.

When Should I Choose Copper Flex Circuits?

You should choose copper flex circuits if you need:

- Exceptionally Low Switch Resistance

- Copper flex membrane switches have a closed loop resistance of <10Ω, much lower than silver-printed switches with <100Ω resistance.

- Small and Thin

- Since copper has excellent conductivity, copper traces can be made significantly thinner than silver traces (0.1mm vs 0.3mm). Copper is also much more resistant to electro-migration, so copper traces can be placed closer together, resulting in a significantly smaller package.

- Vibration Resistance

- Flex circuits can tolerate vibrations better. Heavier solid copper traces are more durable.

- Complex Circuitry

- If polyimide film is used, both active and passive components can be soldered onto the circuit, allowing copper flex switches to better withstand high vibration environments.

- Thermal Resistance

- Polyimide film has a low coefficient of thermal expansion, is able to withstand high temperatures (up to 400°C), and can dissipate heat better, thus polyimide flex circuits are very suitable for high temperature applications.

Otherwise, we recommend choosing silver flex membrane switches instead, as they are significantly more environmentally-friendly and affordable option.

Features and Benefits of Silver Flex Membrane Switches

- Cost Effective

- Screen-printing silver ink costs significantly less than copper-etching, hence silver flex circuits are much more economical than copper flex circuits. Silver flex circuits are also significantly cheaper than bulky electromechanical switch assemblies.

- Environmentally Friendly

- The production of silver flex circuits via screen-printing does not require the use of harsh chemicals or produce hazardous waste, hence silver flex circuits are better for the environment.

- Moisture Resistant

- The sealed construction of a silver flex circuit offers inherent moisture resistance.

- Easy to Clean

- Silver flex membranes contain no gaps or external moving parts that could trap contaminants, making them easily to clean and highly appropriate for applications where cleanliness is a concern.

- Small, Thin, Light and Space Efficient

- Silver flex switches, made of lightweight polymer sheets and silver ink, are much smaller, thinner, and lighter than bulky electromechanical switch assemblies.

- Design Flexibility

- Since silver flex circuits are so thin and flexible, designers have an immense amount of flexibility in configuring silver flex circuits to fit into almost any imaginable size or shape.